To learn more, discover in our latest case study how implementing digital twins in your supply chain can improve efficiency, minimize risks, and reduce costs.

This blog post is based on the presentation given at the anyLogistix Conference 2023 by Prof. Dr. Dr. habil. Dmitry Ivanov from the Berlin School of Economics and Law. The author has a legacy of over 10 books and 130 research papers and brings unmatched expertise to the table.

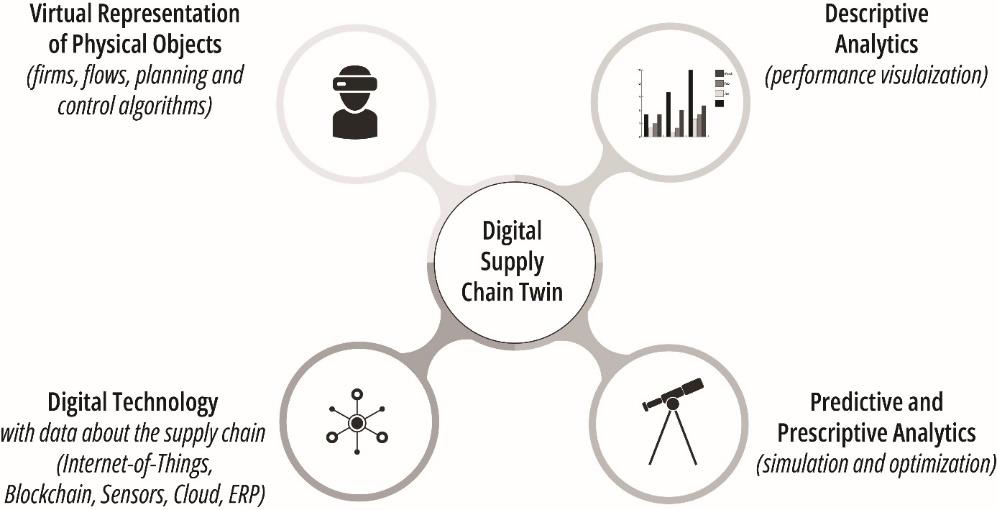

A digital twin in a supply chain is much more than a simulation model. It's a virtual system that combines data visualization, technology, and analytics to help make better decisions in supply chain operations. As you look into the future of digital twin technology, it's evident that it will play a key role in transforming supply chain management.

But what is the difference between a simulation model and a digital twin? At first sight, it may seem that they are quite similar, but in fact, they have many key differences. Unlike simulation modeling, where engineers need to set the model's parameters, a digital twin is supported by real-time data, integrating it from both internal and external sources.

Digital twins in the supply chain

However, the biggest difference is knowledge. Digital twins are based on it. Moreover, they are excellent at transferring and, importantly, generating new knowledge. Technologies like intelligent digital twins (iDT) further improve these capabilities through the easier and smarter use of analytics and machine learning. In simple terms, an intelligent digital twin is a system that uses artificial intelligence to collect and analyze data, imitate human decision-making, and create new knowledge through human-AI collaboration.

In this blog post, we will talk more about digital twins, their kinds, and the future awaiting this technology in the supply chain. Follow along to explore how intelligent digital twins will become essential in managing supply chain disruptions, including unpredictable events like COVID-19.

Contents:

According to PwC, digital technologies in the supply chain have evolved significantly in recent years, becoming one of the most popular topics in logistics.

These technologies are broadly classified into six categories:

Their applications span across network and plant levels, incorporating advancements such as the Internet of Things, 5G, blockchain, product sensors, cyber-physical systems, and other equally important technologies.

The digital twin is one of the concrete implementations of these technologies. Digital twins in supply chain and operations management are complex and multifaceted, representing a significant segment in the future development of this technology.

They are defined as virtual systems consisting of three major components:

A digital twin for supply chain stress testing and resilience (click to enlarge)

Digital twins play an important role in supply chain stress-testing. They combine disruption data, such as natural disasters and financial crises, with supply chain models. This approach enables both proactive and reactive strategies, assessing and responding to potential impacts using past and real-time data. It improves supply chain resilience so that supply chains can be better prepared and respond faster to various disruptive scenarios.

The development of digital twins in supply chain management has seen remarkable progress. This development is characterized by three levels:

Three levels of digital twins (click to enlarge)

Initially, the basic digital twins' models focused mainly on visualizing and modeling supply chains. Then they evolved into cognitive systems capable of mimicking human decision-making processes. Now, we're moving towards intelligent systems that not only mimic but also create new knowledge and decision-making algorithms. Those systems, known as intelligent digital twins, lead us into a future with more self-reliant and sophisticated tools for managing supply chains.

These advancements in digital twin technology are directly linked to the evolution of resilient systems in supply chain management. They enhance predictive, adaptive, and proactive capabilities for supply chain risk mitigation and managing disruptions.

There are three distinct kinds:

Digital twins have become crucial in dealing with the “unknown known” – a significant challenge in resilience. They are based on theories of systems, where each one is understood in terms of two spaces: system and uncertainty. System space is controllable, observable, and predictable, while uncertainty space is completely the opposite.

So, digital twins are particularly valuable in managing unpredictable elements like the COVID-19 pandemic. They shift the focus from uncontrollable uncertainties to controllable aspects within the system space. Moreover, they improve supply chain mapping and illuminate “digital shadows,” revealing undisclosed suppliers whose disruptions could pose significant risks.

Now we are moving toward intelligent digital twins. Their development based on human-AI collaboration is a key to improving supply chain management. It combines the best of both worlds: human expertise and the big data processing capabilities of artificial intelligence. This teamwork makes supply chain management smarter and more efficient.

Platforms like anyLogistix are solutions in this direction, helping to make supply chain networks more adaptable and resilient. Looking ahead, the shift from offline modeling to data-driven digital supply chains is evident.

Human-machine collaboration: toward intelligent digital twins (click to enlarge)

For supply chain managers, understanding how real-time data shapes decision-making is crucial. In the future, the decisions that they make will be largely shaped by technologies such as intelligent digital twins and tools like anyLogistix. Digital twins are key to making supply chains more resilient, agile, and intelligent, helping businesses deal with both familiar and unexpected challenges in the supply chain.

To learn more, discover in our latest case study how implementing digital twins in your supply chain can improve efficiency, minimize risks, and reduce costs.

Then, to gain even more insights on this interesting topic, watch the video below of Prof. Dr. Dr. habil. Dmitry Ivanov's presentation at the anyLogistix Conference 2023.

The slides from the presentation are available in PDF.