We can already say that 2020 was a difficult year in many spheres of life. For global and local economies, the COVID-19 pandemic, closed borders and total supply chain uncertainty have caused a lot of damage.

In that context, it is no surprise that businesses have begun to think more and more about the importance of supply chain resilience and reliability. During this period of global disruption and instability, supply chain resilience and reliability have proven to be much more valuable than maximizing profits here and now.

However, what specific actions are needed to make your supply chain more resilient? What characteristics should a robust supply chain have? Let us walk through what is needed for supply chain resilience and reliability and show how anyLogistix can help turn theory into reality.

By supply chain resilience we mean its preparedness for any kind of disruption. The quicker your supply chain can respond to disruption and recover, the more resilient it is. A truly resilient supply chain keeps operating when things go wrong — even during events such as earthquakes, fires, and pandemics. Supply chain reliability is about performance stability: a reliable supply chain can operate smoothly for years and deliver consistently high efficiency rates. So, we want our supply chains to be both reliable and resilient: to be stable and efficient as well as resistant to disruptions.

Unfortunately, in most cases resilience and reliability in a supply chain are opposed to cost-effectiveness. Any safety measure you take will ultimately cost you additional money, time, or effort. Therefore, when discussing strategies for a more robust supply chain, we must think about the balance between precaution and cost-effectiveness, and not how to foresee and prevent every possible problem.

So, what actions will help achieve supply chain resilience.

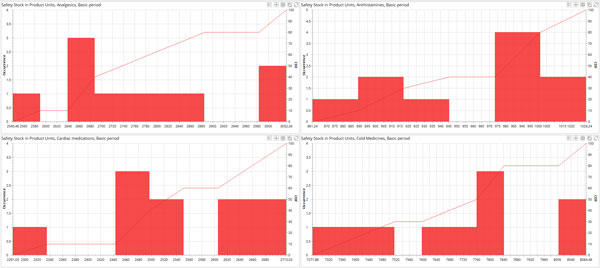

Safety stock is a level of extra stock that is maintained to mitigate the risk of stock-outs and enable the provision of customer service levels. A high level of safety stock provides a large buffer against disruption and makes your supply chain more resilient, but it also increases inventory holding cost. On the contrary, a low level of product availability lowers the inventory holding cost but can lead to an increase in the number of customers not served on time. That makes your supply chain more vulnerable to supply interruptions, demand fluctuations, or any other kind of disruption.

To find a balanced, optimal, product stock volume you can carry out a safety stock planning using anyLogistix software. The result of the Safety Stock Estimation experiment offers optimal product stock volume to provide a required service level.

Learn more about safety stock estimation >>

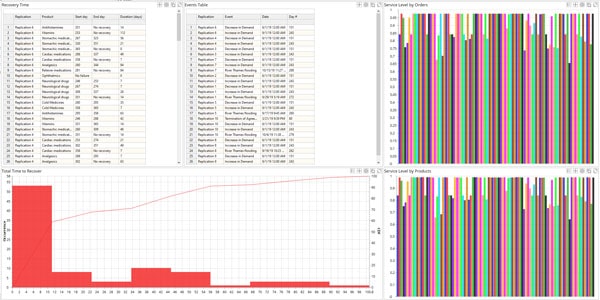

Supply chain risk analysis can help identify and analyze potential issues that could negatively impact a company’s performance. It will also help find a way to avoid or mitigate such risks. anyLogistix provides users with Simulation and Risk Analysis experiments. These experiments help stress-test a supply chain in emergencies, to analyze the results, and to implement the changes necessary to make a supply chain more reliable and resistant to disruptions.

Learn how anyLogistix software enhances supply chain risk management>>

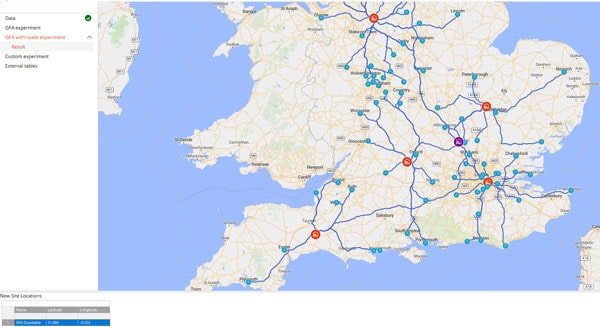

In some cases, you can reduce risks and protect yourself in the face of instability by diversifying your supply network. Manufacturing and sourcing diversification can be a key to stability, especially in international supply chains or in the regions with unstable economic and political situations. Brownfield analysis in anyLogistix helps expand an existing network in an optimal way. It will generate the number of additional facilities required, along with their locations, and help to integrate them into the existing supply chain structure. The result makes your supply chain more resilient and reliable.

Learn more about supply chain restructuring with anyLogistix>>

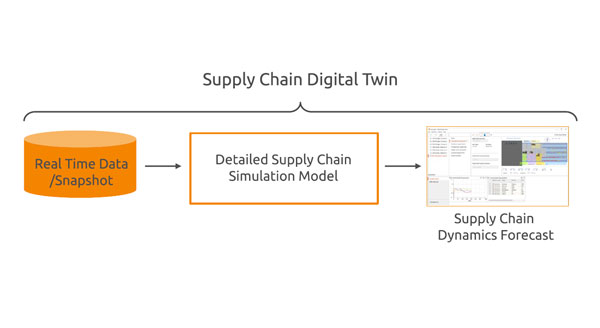

Supply chain digital twins can help achieve resilience and reliability in many ways. They allow you to dynamically respond to disruptions once they occur through the live modeling of recovery scenarios. With digital twin you can:

Learn more about supply chain digital twins >>

When building a resilient supply chain, it is impossible to get a straightforward and universally applicable action plan. Every supply chain is unique and has its own strengths and weaknesses. Nevertheless, anyLogistix is a universal tool for building a resilient and reliable supply chains. It combines analytical and simulation modeling methods that provide you with a powerful toolset to capture the uniqueness of your supply chain, improve it in every aspect, and stress-test its performance under the different conditions.

You will never be able to predict every disruption, but with anyLogistix you can be well prepared for a range of possible risks, giving you a chance to respond to disruption and recover your supply chain before losses become critical. This is exactly what we mean by supply chain resilience.