Decision Lab wanted to test whether they could perform supply chain redesign for a major UK wastewater utility using anyLogistix. The team aimed to model the same network more efficiently without coding and still provide actionable insights for supply chain planning and logistics cost reduction.

Using anyLogistix, the Decision Lab team quickly configured transport flows, vehicle capacities, and sourcing and routing policies and conducted strategic experiments such as facility consolidation and route changes. To uncover cost reduction opportunities, they focused on transportation costs, the process’s largest energy consumer.

anyLogistix’s visual interface and built-in logic enabled analysts to configure, run, and compare multiple scenarios within hours—significantly faster than with traditional simulation tools.

Decision Lab is a UK-based analytics and decision-support consultancy specializing in simulation modeling, artificial intelligence, and data science. Working across sectors such as defense, automotive, energy, and consumer goods, they help organizations solve complex operational challenges with simulation and analytical tools.

One of Decision Lab’s projects addressed a high-stakes logistics challenge in the £9.2 billion UK wastewater industry. The sector handles 16 billion tons of wastewater daily and is increasingly focused on converting waste into energy through anaerobic digestion.

The client, a major UK wastewater utility provider, sought to optimize its wastewater-to-energy supply chain, with the primary goal of logistics cost reduction.

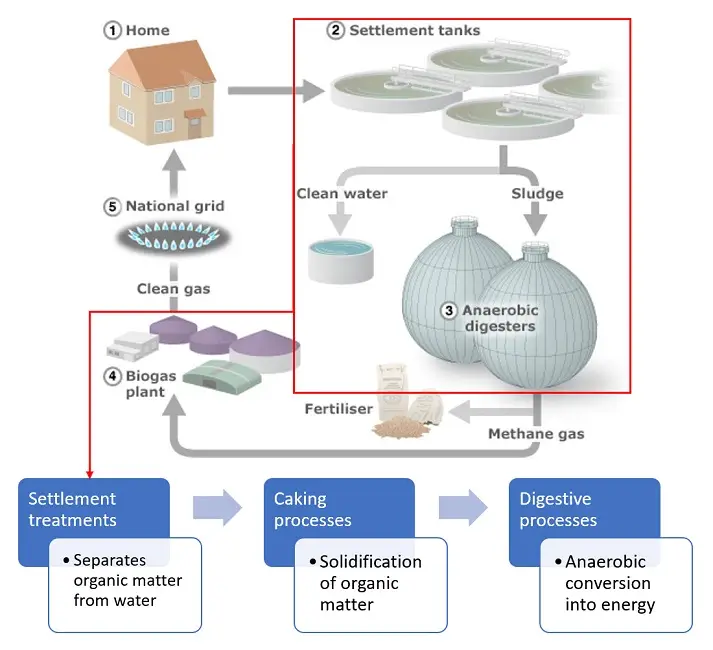

The logistics involved moving organic matter between wastewater treatment works (WwTWs), intermediate caking facilities (ICFs), anaerobic digestion sites (ADs), and finally, to the energy grid. A process both operationally complex and energy intensive, with high potential for logistics cost reduction.

Wastewater treatment process optimization: systems diagram with model scope in red

In 2018, Decision Lab built a simulation model using AnyLogic in just three days to assess logistics efficiency and maximize the energy return on energy invested. The model outlined how organic matter flowed through various facilities, compared centralized and decentralized digestion, and tested alternative routing strategies.

Wastewater treatment simulation model in AnyLogic (click to enlarge)

While powerful, the AnyLogic model required coding and simulation expertise, limiting its accessibility for non-specialists. The team wanted to test whether they could perform supply chain redesign using anyLogistix. They planned to model the same network more efficiently without coding and still provide actionable insights for supply chain planning and logistics cost reduction.

The goal was to rebuild the wastewater-to-energy network using anyLogistix’s built-in supply chain modeling features. It included facilities representing WwTWs, ICFs, ADs, and the energy grid. Organic matter and energy were treated as supply chain products, and three transport segments were modeled: raw matter to caking, caked matter to digestion, and energy to grid.

Wastewater supply chain redesign in anyLogistix (click to enlarge)

Using anyLogistix, the Decision Lab team quickly set up transport flows, vehicle capacities, sourcing and routing policies, and conducted strategic experiments such as facility consolidation and route changes. To uncover opportunities for logistics cost reduction through targeted supply chain redesign, they focused on transportation costs, the largest energy consumer in the process.

Importantly, all of this was accomplished without writing custom code. anyLogistix’s visual interface and built-in logic enabled analysts to configure, run, and compare multiple scenarios within hours—significantly faster than traditional simulation tools.

anyLogistix was chosen for its ability to combine optimization and simulation in one environment. Unlike general-purpose simulation tools, anyLogistix is tailored to supply chain professionals, enabling rapid modeling, scenario analysis, and real-world visualization without programming. Features such as sourcing policy configuration, built-in transport cost calculations, and GIS mapping made it especially effective for visualizing and adjusting the logistics network dynamically.

While the original AnyLogic model offered flexibility and deep control, anyLogistix enabled faster insights, greater accessibility, and quicker iteration. This is crucial for supply chain planners who need to test ideas under time pressure and explore cost-effective supply chain redesign strategies.

In just a few hours, Decision Lab recreated the core functionality of the 2018 model in anyLogistix. The rebuilt model enabled rapid scenario testing with quantifiable outcomes:

Results of scenario testing in the anyLogistix model (click to enlarge)

This approach demonstrated how resilience and efficiency could be co-designed. It also showed that supply chain trade-offs between transport costs, infrastructure, and service levels can be quickly validated through simulation and used to guide effective supply chain redesign.

This case illustrates how anyLogistix enabled Decision Lab to reimagine a complex logistics network with speed and clarity. By shifting from code-intensive modeling to supply chain-oriented tools, teams can build resilience, perform logistics cost reduction, and make faster, better decisions.

This case study was presented by Adam Coleman from Decision Lab at the anyLogistix Conference 2025.

The slides are available as a PDF.